Flexi Pick Systems

Overview

Tailored Robotic Solutions for Your Automation Needs

Our FLEXIPICK systems offer state-of-the-art robotic solutions engineered to meet the dynamic demands of modern industries. Designed for reliability, precision, and flexibility, these robots are the cornerstone of any efficient production line.

Upto

Labor Cost Reduction

0

%

Upto

Cycle Time Reduction

0

%

6-Axis Robot:

- Key Features:

- High precision and flexibility for complex multi-axis operations.

- Seamless integration into existing workflows.

- Ideal for welding, material handling, machine tending, and assembly tasks.

Manufacturing

Automotive Assembly

Electronics

Customized Fabrication

Specifications:

| Payload | 10 Kgs | ||||||||||||

| Reach | 1500m | ||||||||||||

| Structure | Articulated | ||||||||||||

| Number of Axes | 6 | ||||||||||||

| Repeatability | +/- 0.05 | ||||||||||||

| Max Motion Range |

|

| Max Speed |

|

||||||||||||

| Weight | +/- 150 kg | ||||||||||||

| Mounting Type | Ground Bracket / Ceiling | ||||||||||||

| Operating Temperature | 5° - 45°C |

Application:

Material Handling

Parts Transmission

Machine Management

Stacking

Packing

Assembly

Deburring

Many More

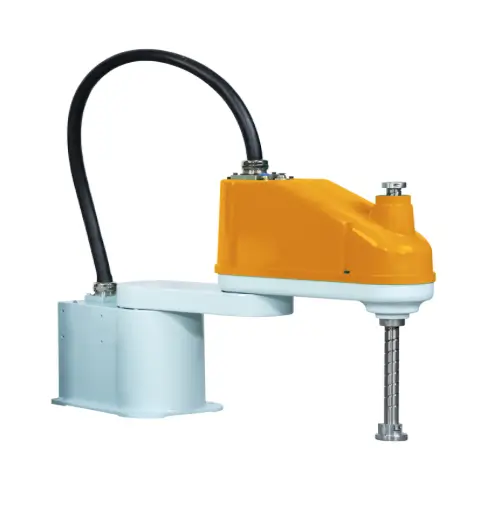

SCARA Robot:

- Key Features:

- Lightweight yet powerful for high-speed operations.

- Optimized for pick-and-place, assembly, and packaging applications.

- Compact design to save space without compromising efficiency.

Pharmaceutical Packaging

Electronics Assembly

Food & Beverage Sorting

Precision Tooling

Specifications:

| Payload | 5 Kgs | ||||||||

| Reach | 600m | ||||||||

| Structure | Absolute value servo | ||||||||

| Number of Axes | 4 | ||||||||

| Repeatability | +/- 0.03mm | ||||||||

| Max Motion Range |

|

| Max Speed |

|

||||||||

| Weight | +/- 29kg | ||||||||

| Mounting Type | Ground Bracket / Ceiling | ||||||||

| Operating Temperature | 5° - 45°C |

Application:

Material Handling

Parts Transmission

Machine Management

Stacking

Packing

Assembly

Deburring

Many More

Comparison:

| Parameter | Manual Pick and Place | Robotic Pick and Place |

|---|---|---|

| Speed (Operations per minute) | 10–20 cycles/min | 60–150+ cycles/min (3–10× faster) |

| Labor Cost | High (wages, training, turnover) | Lower (CAPEX, low OPEX) |

| Accuracy | 85–90% (fatigue-prone) | 99.5%+ (high repeatability) |

| Error/Rework Rate | 5–10% | <1% |

| Equipment Cost Over Time | – | Up to 40–60% lower TCO over 3–5 years |

| Downtime / Fatigue | Frequent breaks, shift-dependent | 24/7 continuous operation |

| Return on Investment (ROI) | Slower | ~12–24 months in most industries |

| Space Optimization | Lower | Compact & programmable for flexible layouts |

| Flexibility | Limited | Easily reprogrammable for SKUs, sizes, weights |

Use Cases:

| Title | Problem Solved | Tech Enablers | Value Delivered |

|---|---|---|---|

| E-commerce Order Fulfillment Picking | Manual picking is slow and error-prone | CV, barcode scanners, suction grippers | Higher order accuracy, faster fulfillment |

| Food & Beverage Sorting (Fruits, Bakery, Packaged Goods) | Sorting by hand is inconsistent and unhygienic | Vision-based defect/shape detection, food-safe grippers | Improves hygiene, consistency, and speed |

| Electronics Component Placement (PCBs, Assemblies) | Human placement lacks precision; speed is limited | High-speed arms, micro grippers, force sensors | Micron-level accuracy, 24/7 operation |

| Plastic Injection Mold Part Picking | Manual removal slows down mold cycle times | Heat-resistant grippers, part ejectors, bin stacking | Faster cycles, protects part quality |

| Pharma Vial or Blister Pack Handling | Contamination risk and bottlenecks in packaging | Sterile-compatible arms, vacuum grippers, conveyors | Compliance with GMP; zero human touch |

| Kitting & Assembly Line Feeding | Workers waste time collecting multiple parts | Vision-guided pick from bins, flexible part feeders | Boosts assembly line speed and accuracy |

| Palletizing / De-palletizing in Warehouses | Heavy/manual labor is slow and causes injury | 6-axis arms, weight sensors, pattern logic | Safer and faster handling of cartons or crates |

| Fast-moving Consumer Goods (FMCG) Packaging | Speed bottlenecks and inconsistent placement | Delta robots, conveyor tracking, end-of-line packaging | Scalable to 200+ picks/minute with minimal downtime |

| Bin Picking of Irregular Objects (Mixed Part Sorting) | Traditional robots can't handle shape variability | 3D vision, AI grasping models, adaptive gripping | Enables automation in unstructured environments |

| Medical Sample Sorting in Labs | Manual handling causes delays and contamination | Tube grippers, barcode scanning, CV-based sorting | Efficient, traceable, and safe lab automation |