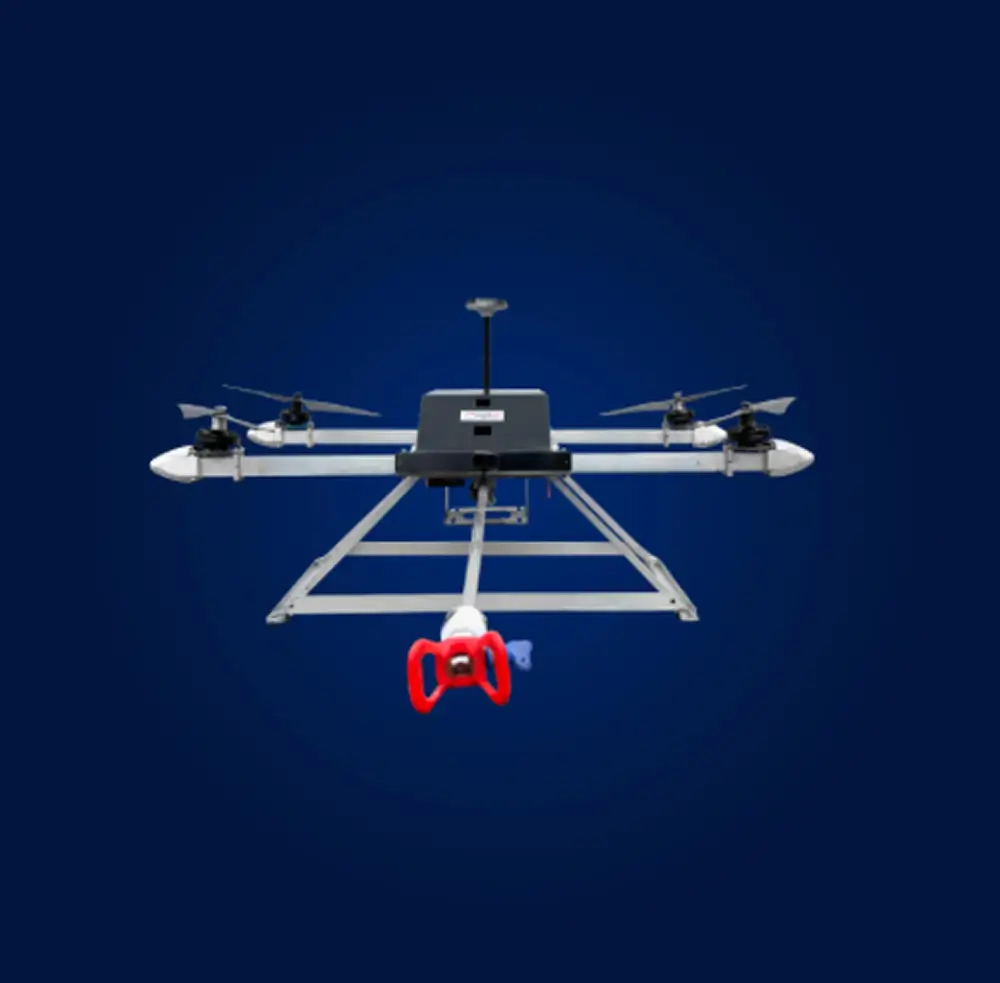

Paint Spraying Using Drones

Overview

The Rise of Drone-Based Paint Spraying

In the modern era of technology-driven solutions, drone-based paint spraying has emerged as a groundbreaking innovation. This method leverages the capabilities of advanced unmanned aerial vehicles (UAVs) to redefine how surfaces are coated. Whether for industrial projects, infrastructure maintenance, or creative applications, drone-powered paint spraying offers unparalleled advantages over traditional methods.

Reduction in Labour Costs.

0

%

CAGR growth through 2022 - 2030.

23

%

Advantages of Paint Spraying Using Drones

Compatible with multiple types of paints and coatings, offering flexibility for diverse projects.

Enhanced Efficiency

Drones are designed to cover large areas quickly and with minimal human intervention, significantly reducing project timelines.

Automated flight paths ensure consistent coverage without overlaps or missed spots.

Automated flight paths ensure consistent coverage without overlaps or missed spots.

Unmatched Accessibility

Drones can reach hard-to-access areas, such as high-rise buildings, bridges, and large industrial tanks, eliminating the need for scaffolding or cranes.

Reduced risk for workers, as there is no need for them to operate at dangerous heights.

Versatility

Ideal for various applications, including industrial coatings, architectural projects, creative murals, and anti-corrosion treatments.

Cost-Effectiveness

Reduced labor and equipment costs translate into significant savings.

Efficient use of materials minimizes waste, making the process environmentally friendly.

Precision and Uniformity

Equipped with advanced sensors and AI, drones ensure precise spray patterns for an even coat of paint.

Real-time adjustments account for environmental factors such as wind, ensuring a superior finish.

Advantages of Paint Spraying Using Drones

Compatible with multiple types of paints and coatings, offering flexibility for diverse projects.

Enhanced Efficiency

Drones are designed to cover large areas quickly and with minimal human intervention, significantly reducing project timelines.

Automated flight paths ensure consistent coverage without overlaps or missed spots.

Automated flight paths ensure consistent coverage without overlaps or missed spots.

Unmatched Accessibility

Drones can reach hard-to-access areas, such as high-rise buildings, bridges, and large industrial tanks, eliminating the need for scaffolding or cranes.

Reduced risk for workers, as there is no need for them to operate at dangerous heights.

Versatility

Ideal for various applications, including industrial coatings, architectural projects, creative murals, and anti-corrosion treatments.

Cost-Effectiveness

Reduced labor and equipment costs translate into significant savings.

Efficient use of materials minimizes waste, making the process environmentally friendly.

Precision and Uniformity

Equipped with advanced sensors and AI, drones ensure precise spray patterns for an even coat of paint. Real-time adjustments account for environmental factors such as wind, ensuring a superior finish.

Comparison

| Metric | Traditional Hand Painting | Drone-Based Painting |

|---|---|---|

| Coverage Speed | 100–150 sq.ft/hour | 400–800 sq.ft/hour (up to 5× faster) |

| Labor Requirement | 2–4 workers per site | 1–2 operators for multiple drones |

| Precision | Variable, prone to overspray | Controlled spray with consistent output |

| Downtime / Setup Time | High (scaffolding, prep time) | Low (minutes to deploy drone) |

| Worker Safety Risk | High (height, chemicals, ladders) | Significantly reduced |

| Paint Wastage | ~20–30% | ~5–10% with automated control |

Use Cases

| Use Case Title | Problem Solved | Tech Enablers | Value Delivered |

|---|---|---|---|

| Automated Surface Coverage for Large Industrial Structures | Manual painting is slow, dangerous, and inconsistent | GPS, SLAM, Automated Spray Control | Faster, safer painting with reduced labor cost |

| 3D Surface Mapping & Paint Path Planning | Inefficient or incomplete coverage planning | LiDAR, Computer Vision, AI Path Planning | Optimal coverage, time savings, material efficiency |

| Corrosion Detection & Targeted Repainting | Wasteful overpainting and missed degradation | Vision, IR Sensors, Rust Detection Models | Paints only affected areas; reduces waste and extends surface life |

| Paint Thickness Auditing & Progress Monitoring | Inconsistent quality, rework due to over/under-spraying | Paint sensors, CV for surface analysis | Quality assurance, compliance, digital audit trails |

| On-Demand Maintenance Triggering via Degradation Prediction | Maintenance is too early or too late | ML on degradation data, CV anomaly detection | Predictive repainting reduces downtime and long-term costs |

| Fleet Orchestration & Job Scheduling | Single drone usage limits scalability | Cloud platform, multi-drone control systems | Maximizes drone utilization and project throughput |

| VOC Emission Monitoring & Environmental Compliance | Regulatory risk from volatile paint compound emissions | VOC sensors, real-time logging | Legal compliance and safer job site certification |

| AR-based Post-Job Inspection Visualization | Hard to verify surface coverage manually | AR devices, overlay of coverage maps | Easy client verification, post-job transparency |

| Use Case Title | Problem Solved | Tech Enablers | Value Delivered | Impact | Feasibility |

|---|---|---|---|---|---|

| Automated Surface Coverage for Large Industrial Structures | Manual painting is slow, dangerous, and inconsistent | GPS, SLAM, Automated Spray Control | Faster, safer painting with reduced labor cost | High | High |

| 3D Surface Mapping & Paint Path Planning | Inefficient or incomplete coverage planning | LiDAR, Computer Vision, AI Path Planning | Optimal coverage, time savings, material efficiency | High | Medium |

| Corrosion Detection & Targeted Repainting | Wasteful overpainting and missed degradation | Vision, IR Sensors, Rust Detection Models | Paints only affected areas; reduces waste and extends surface life | Medium | Medium |

| Paint Thickness Auditing & Progress Monitoring | Inconsistent quality, rework due to over/under-spraying | Paint sensors, CV for surface analysis | Quality assurance, compliance, digital audit trails | High | Medium |

| On-Demand Maintenance Triggering via Degradation Prediction | Maintenance is too early or too late | ML on degradation data, CV anomaly detection | Predictive repainting reduces downtime and long-term costs | High | Low |

| Fleet Orchestration & Job Scheduling | Single drone usage limits scalability | Cloud platform, multi-drone control systems | Maximizes drone utilization and project throughput | Medium | High |

| VOC Emission Monitoring & Environmental Compliance | Regulatory risk from volatile paint compound emissions | VOC sensors, real-time logging | Legal compliance and safer job site certification | Medium | Medium |

| AR-based Post-Job Inspection Visualization | Hard to verify surface coverage manually | AR devices, overlay of coverage maps | Easy client verification, post-job transparency | Medium | Low |